Inverted Windproof Zip Screen

Product Name: Inverted Windproof Zip Screen

Fabric Material: Glass Fiber + PVC

Fire Rating: National Standard Grade B1

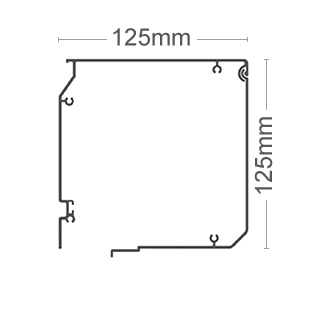

Track Material: Aluminum Alloy

Light Blocking Rate: 50%-100% Light Blocking Rate

Wind Resistance: Capable of resisting winds up to Force 7

Control Methods: Voice Control, Wireless Remote Control

Tel:(+86)133-3626-2319(Manager Kim)

Tel:(+86)133-3626-2319(Manager Kim) E-mail:13011761258@163.com

E-mail:13011761258@163.com Address:Workshop No. 1, Shandong Xinqu Energy Co., Ltd., No. 3886, Tianqu East Road, Economic and Technological Development Zone, Dezhou City, Shandong Province

Address:Workshop No. 1, Shandong Xinqu Energy Co., Ltd., No. 3886, Tianqu East Road, Economic and Technological Development Zone, Dezhou City, Shandong Province